Hexflens noten

Stuur onderzoek

The wide base of the hex flange nuts distribute the load evenly and reduces surface damage.The hex shape fits standard tools, and materials like galvanized steel fight rust. Some versions have serrated flanges for extra grip on smooth surfaces. Saving time and parts.

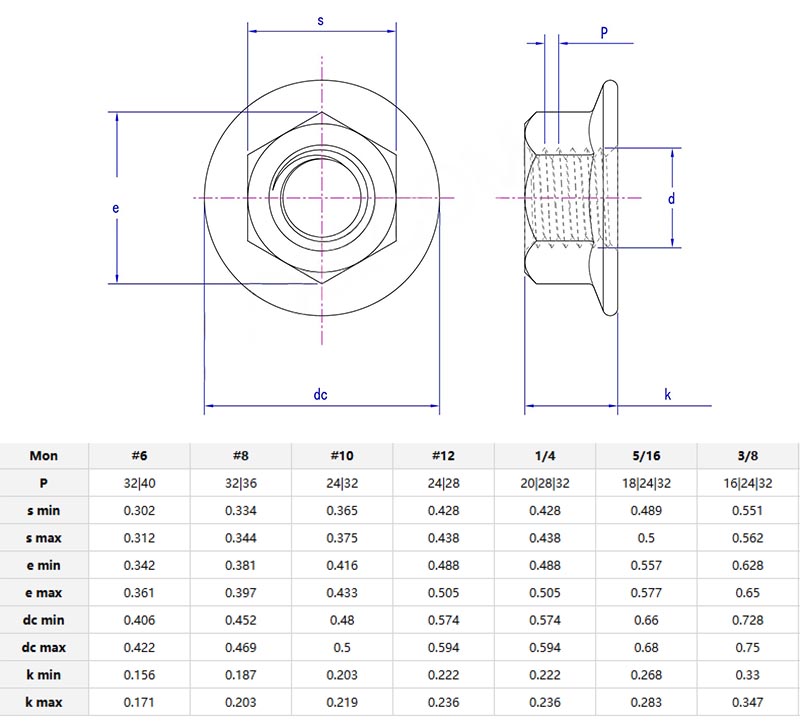

Product details and parameters

Hex flange nuts are six-sided nuts with a built-in flange (wide, flat edge) at the bottom. The flange acts like a gasket in that it protects the surface by spreading the pressure while reducing looseness caused by vibration. It is made of steel, stainless steel or coated alloys and is used in machinery, vehicles or outdoor equipment where bolts face vibrating or uneven surfaces. Customers do not need to use separate gaskets.

Hex flange nuts are common in automotive manufacturing (wheel hubs, engine brackets), construction (steel beams, scaffolding), and agriculture (tractor attachments). Factories use them on conveyor belts, while DIYers rely on them for trailers, bikes, or garage shelving. Anywhere vibrations or weather threaten bolts, these nuts step up.

Hex flange nuts are low-maintenance. Check for rust or bent flanges over time. For salty or wet environments, choose stainless steel. Reuse them if threads are clean, but replace if the flange cracks. Avoid over-tightening, which can warp softer materials.

Why They Beat Regular Nuts

Hex flange nuts solve two problems: loosening and surface damage. There is no separate washer and the flange adds stability. They are a little more expensive than regular nuts, but can save time and money in the long run.